As an industry-leading, integrated solution provider, Lummus Digital offers a diversified technology portfolio for the Oil & Gas sector, built upon the AI/ML capability of the mcube™ platform. Our digital solutions address the operating challenges across the refinery, enabled by the deep experience of partner companies Lummus Technology and CLG.

Digital solutions for the refinery cater to the various stages of asset lifecycle for operations and maintenance. Our solutions empower our global customers across the Oil & Gas sector by adding to their bottom line with payback of less than 6 months and an ROI of 50%+ in most cases.

CDU/VDU Optimization

Digital optimization boosts the efficiency of the crude and vacuum distillation units (CDU/VDU) by reducing losses, improving side-stream yields and unlocking cost savings across your operations.

At the core of this optimizer is a hybrid AI model designed to maximize the flow rates of Side Stream 1, Side Stream 2, and SPVGO by optimizing the movement of the Vacuum Tower Bottom (VTB) product into the column’s middle section. Leveraging real-time DCS data, it ensures that viscosity, flash point, and VTB penetration number remain within specification limits.

With real-time predictions of downstream quality parameter values and improved product recovery, your operations are transformed with enhanced efficiency and profitability!

Pain Point

Crude Blend Uncertainty

Benefit

Crude Mix Clarity: Our crude mix model accurately determines the processed blend by integrating analyzer API values with user-provided crude mix data.

Pain Point

Unstable Operation During Crude Changeovers

Benefit

Dynamic Crude Optimization: The model adapts to varying crude blends, providing optimized set points for each combination, ensuring smooth operations and stability.

Pain Point

Loss of High-Value Streams

Benefit

Maximized Product Value: The model optimizes VTB blending with higher-value middle streams, keeping all quality parameters within spec limits to maximize profitability.

Pain Point

Low Frequency Sampling of Side-Streams and Vacuum Tower Bottom

Benefit

Real-Time Quality Predictions: Our model delivers high-frequency, real-time predictions of key quality metrics, enabling faster, more accurate control.

Performance Metrics

Performance Deviation Prediction

Operator enters the estimated crude mix on the dashboard and initiates the run.

Key Parameter Monitoring

The Crude Mix Model calculates the accurate crude mix and displays the results on the dashboard.

Process and Efficiency Trends

Every two hours, the prediction model runs to predict the Viscosity, Flash Point, and VTB Penetration Test values at operating conditions.

Operational Benchmarking

Using the corrected crude mix and predicted product quality parameters, the Optimizer Model runs and populates a table of actual and optimized/recommended values.

Actionable Insights for Improvement

A comparison plot between “Current Operation” and “Optimized Operation” is displayed on the dashboard for operator action.

Hydrocracker Optimization

Hydrocracker Optimization delivers maximum conversion by utilizing DCS and Feed Quality data in real time. The AI/ML platform defines essential DCS setpoints and recommendations for plant operators and process engineers, enabling consistent achievement of target conversion rates.

Our model begins by accurately predicting the maximum achievable conversion, leveraging feed quality detail from Stage 1 and Stage 2, such as distillation profile, sulfur content, nitrogen, and asphaltenes. The optimizer then generates precise DCS operator setpoints—such as Heater COT, Reactor CAT, and hydrogen flow—enabling operators to achieve optimal conversion efficiently and process reliability.

Pain Point

Unclear Potential Conversion

Benefit

Dynamic Target Conversion: Instantly adjusts to feed quality changes.

Pain Point

Inability to Boost Reactor Performance Without Vacuum Tower Fouling

Benefit

Optimized Reactor Efficiency: Utilize our Conversion and SHFT model to boost conversion while minimizing vacuum tower fouling.

Pain Point

Insufficient Stage 2 Feed and Product Quality values

Benefit

Pain Point

High Hydrogen Consumption

Benefit

Reduced Excess H2: Lower H₂ consumption during operations.

Performance Metrics

Performance Deviation Prediction

Utilizes Stage 1 and Stage 2 Feed LIMS data to predict the quality parameters of both Stage 1 and Stage 2 products.

Key Parameter Monitoring

- Fixed Conversion

- Maximum Conversion

Process and Efficiency Trends

Using Stage 1 and Stage 2 Feed Quality data, the model calculates the potential conversion achievable for the given feed quality.

Operational Benchmarking

The model runs and publishes recommended values for operator-controlled setpoints required to achieve maximum possible conversion.

Actionable Insights for Improvement

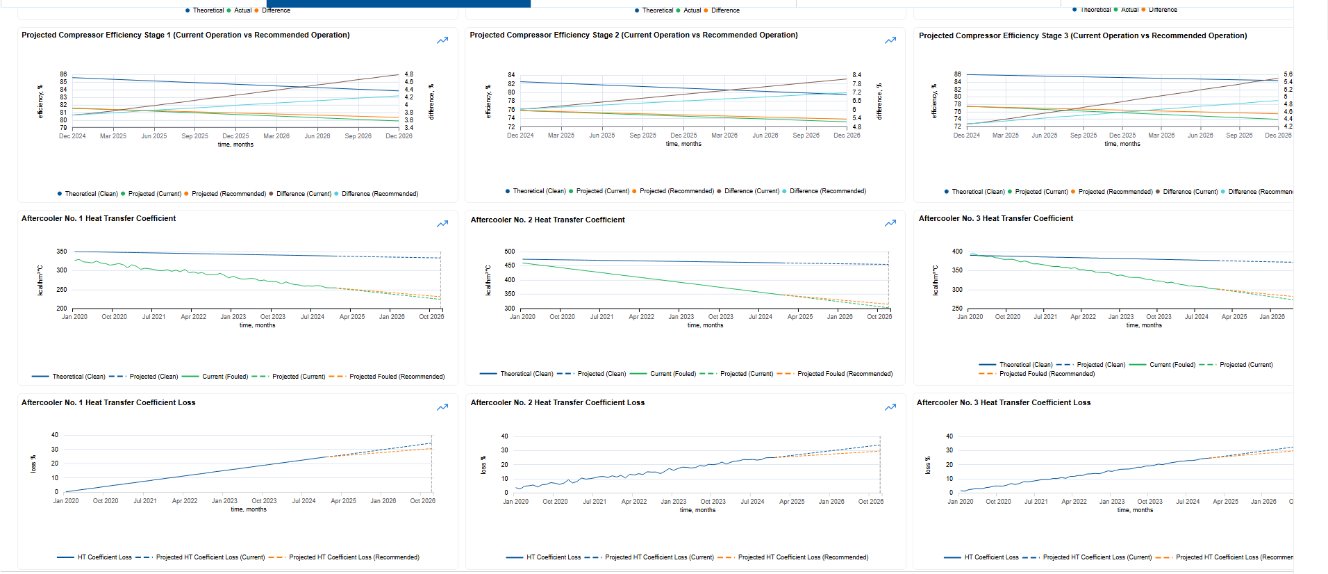

A comparison plot of Current Operation vs. Recommended Operation is displayed on the dashboard.

Hydrocracker

Optimization

LC-Fining

LC-Fining

The hybrid digital solution for LC-FINING optimization integrates physics-based models with advanced data analytics to optimize reactor performance. By dynamically adjusting key parameters—such as temperature and hydrogen flow—and combining real-time plant data with insights into thermodynamics and reaction kinetics, it maximizes product yields, reduces energy consumption, and extends catalyst life. Operators can simulate multiple feedstock scenarios, enabling smarter, data-driven decision-making.

Implement digital solutions to enable increased conversion, real-time predictions of downstream SHFT values, and optimized hydrogen consumption, transforming your operations for enhanced efficiency and profitability.

Pain Point

Unclear Potential Conversion

Benefit

Dynamic Target Conversion: Instantly adjusts to feed quality changes for accurate conversion targets.

Pain Point

Reactor Performance Limited by Vacuum Tower Fouling

Benefit

Optimized Reactor Efficiency: Utilize our Conversion and SHFT model to boost conversion while minimizing vacuum tower fouling.

Pain Point

Insufficient Vacuum Residue SHFT Values

Benefit

Hourly Insights on Vacuum Residue: Leverage our SHFT model for real-time predictions of vacuum residue values.

Pain Point

High Hydrogen Consumption

Benefit

Reduced Excess H2: Lower H₂ consumption during operations.

Pain Point

Reduced Conversion Efficiency Lowers Valuable Product Yields

Benefit

Optimizing temperature and hydrogen flow boosts reactor performance, increasing diesel and naphtha yields while enhancing efficiency and minimizing waste.

Pain Point

Increased Residues Strain Resources

Benefit

Advanced analytics and thermodynamic insights reduce residue, lowering energy and hydrogen consumption while minimizing equipment wear and extending its lifespan.

Pain Point

Catalyst Deactivation Leads to Higher Maintenance Costs and Reduced Refinery Flexibility

Benefit

Extended Catalyst Life: Minimize residue formation and thermal stress using predictive analytics, which reduces wear, maintenance costs, and operational downtime.

Performance Metrics

Performance Deviation Prediction

Key Parameter Monitoring

The Operator can select the mode of Optimization as

- Fixed Conversion

- Maximum Conversion

Process and Efficiency Trends

Using the FOI and predicted SHFT Value, the model calculates the Potential Conversion that can be achieved for the given Feed Quality.

Operational Benchmarking

The model generates and publishes recommended operator-controlled setpoints required to achieve maximum possible conversion.

Actionable Insights for Improvement

The dashboard displays a comparison plot of “Current Operation” vs. “Recommended Operation”, enabling clear visibility into performance gaps and improvement opportunities.

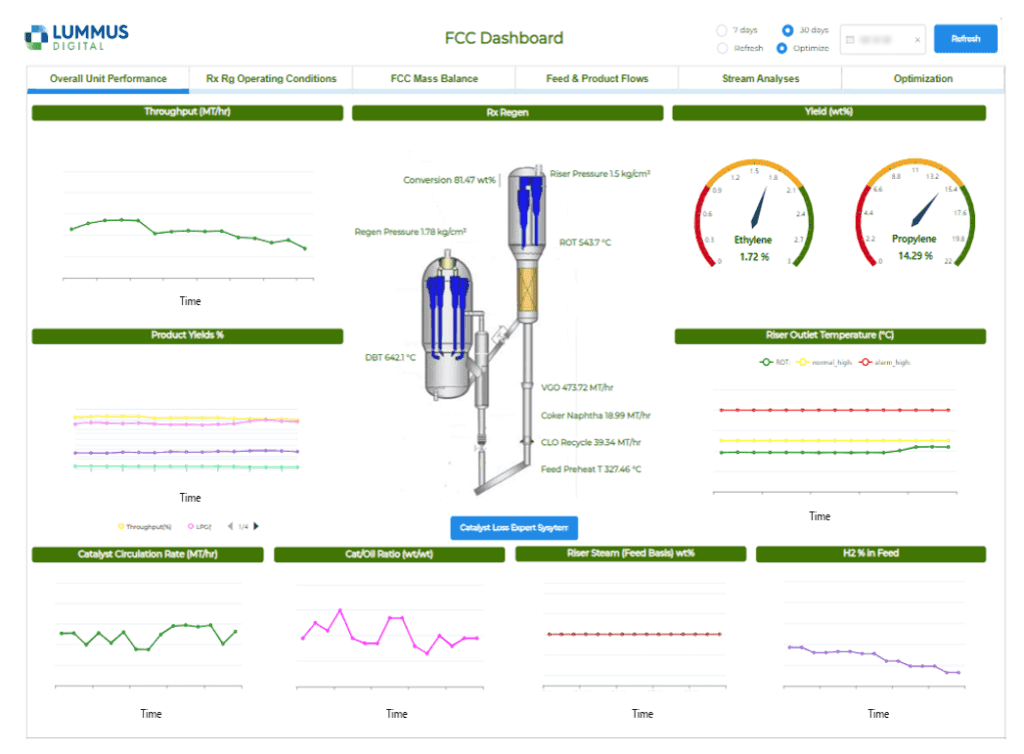

Ethylene/Propylene Optimization in the FCC

Ethylene/Propylene Optimization in the FCC

This solution uses an AI/ML platform to maximize ethylene and propylene yields in FCC operations. Our model provides precise operator setpoints for optimizing key variables in either fixed or variable riser operating temperature scenarios adjusting riser pressure; dispersion steam rate; coker naphtha recycle rate; and dense bed temperature.

Pain Point

Yield Limitations at Maximum Riser Operating Temperature (ROT)

Benefit

Fixed ROT Maximization Optimizer: Provides insights into possible yield increases for both ethylene and propylene.

Pain Point

Uncertainty in Optimization Mode Selection

Benefit

Dual ROT Optimization: Evaluates both fixed and variable ROT scenarios to reveal potential yield improvements.

Performance Metrics

Performance Deviation Prediction

DCS and LIMS data for both feed and product streams are captured, providing essential input for analysis and optimization.

Key Parameter Monitoring

Operators select the optimization mode—Fixed ROT or Variable ROT—to maximize ethylene and propylene (E+P) yield

Process and Efficiency Trends

The optimizer runs hourly based on the last selected optimization mode and the latest DCS and LIMS data, ensuring up-to-date analysis.

Operational Benchmarking

The Results from the optimizer are published on the Dashboard table.

Actionable Insights for Improvement

Comparison plot between “Current Operation” vs. “Optimized Operation“ is shown on the Dashboard.

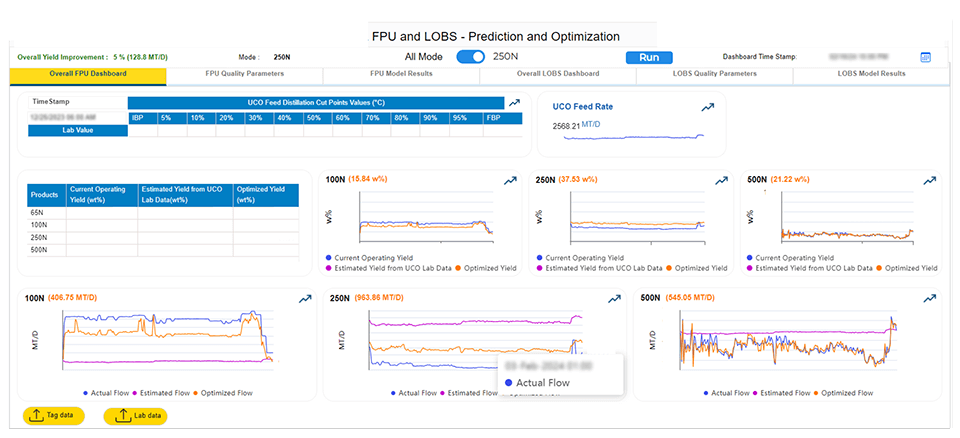

LOBS Optimization

Elevate your production with the LOBS Optimization Advisor—an advanced AI/ML-powered platform engineered to maximize a particular grade cut yields from the FPU and significantly boost lube oil output from the LOBS unit.

Our hybrid model empowers operators with precise setpoints to optimize critical variables in both the FPU and LOBS sections, driving maximum 250N cut yields.

Pain Point

Loss of 250N Yield Potential

Benefit

Enhanced 250N Cut: The model maximizes 250N yield in FPU and boosts 250N lube oil output in LOBS, ensuring maximum product recovery and profitability.

Pain Point

Delayed Detection of Side-Stream Quality Variations

Benefit

High-Frequency Quality Tracking: Real-time sampling of viscosity and pour point in side streams enables precise quality control and rapid adjustments, maintaining optimal output specifications.

Performance Metrics

Performance Deviation Prediction

The operator enters the UCO Feed Quality (Distillation Sample) data on the dashboard for analysis of the feed quality parameters.

Key Parameter Monitoring

The Expected Yield model calculates the expected yields for 65N, 100N, 250N and 500N streams of the FPU and LOBS.

Process and Efficiency Trends

Every hour, the prediction model runs to predict the Viscosity of all side streams, and the formula calculates the Viscosity Index

Operational Benchmarking

Every hour, the prediction model runs to predict the Viscosity of all side streams, and the formula calculates the Viscosity Index.

Actionable Insights for Improvement

Comparison plot between “Current Operation” vs. “Optimized Operation“ is shown on the Dashboard.

Dew Point Prediction and Optimization

Dew Point Prediction and Optimization

Hybrid modeling is a key solution to improve the accuracy of dew point predictions, ensuring optimal conditions for maintaining “On-spec” product quality and avoiding costly operational decisions that impact run time and maintenance costs.

Product Stripper dew point issues often create significant operational hurdles, including off-spec products, hydrocarbon condensation, and decreased throughput. These challenges lead to inefficiencies in separation processes, adversely affecting product quality and escalating reprocessing costs.

To mitigate these issues, operators often increase reboiler heat, resulting in higher energy consumption and diminished plant efficiency.

Additionally, dew point mismanagement can lead to equipment fouling, corrosion, and potential damage to downstream compressors from liquid carryover. This not only drives up maintenance costs and unplanned downtime but also introduces environmental and safety risks associated with venting or flaring.

By addressing dew point management effectively, refineries can enhance performance, reduce costs, and maximize profitability.

Pain Point

Steam Condensation Risks and Fouling Problems

Benefit

Real-time monitoring and adjustments enable operators to maintain optimal operating conditions, enhancing process stability, boosting productivity by 10%, and delivering an annual revenue increase of $100,000 alongside total savings of approximately $250,000.

Pain Point

Unplanned Shutdowns and Increased Maintenance Frequency

Benefit

Optimize energy usage and enhance the equipment lifespan with actionable recommendations based on AI-driven insights and hybrid model approaches.

Pain Point

Lack of Proactive Management

Benefit

Predictive insights inform maintenance schedules, enabling proactive measures to address potential issues and extend equipment life by 20%, saving a medium-sized industrial plant approximately $150,000 annually based on a $750,000 replacement cost every five years.

Performance Metrics

Performance Deviation Prediction

Calculate the dew point with precision and suggest the most optimal top temperature settings to prevent steam condensation from occurring during the process.

Key Parameter Monitoring

Complete monitoring of all parameters, including Naphtha flow, off-gas flow, reflux flow, steam flow, top pressure, and top temperature.

Process and Efficiency Trends

Trend plots for

- Dew point

- Overhead temperature

- Top pressure & Partial pressure

- Reflux flow, Off-gas flow, and Naphtha flow

Operational Benchmarking

Comparison plot and table between “Actual” vs. “Recommended “ for

1. Overhead Temperature

2.Reflux Flow

3.Stripping Steam Flow

Actionable Insights for Improvement

Actionable recommendations (based on comparison with current values) on controllable parameters such as reflux flow and stripping steam flow.

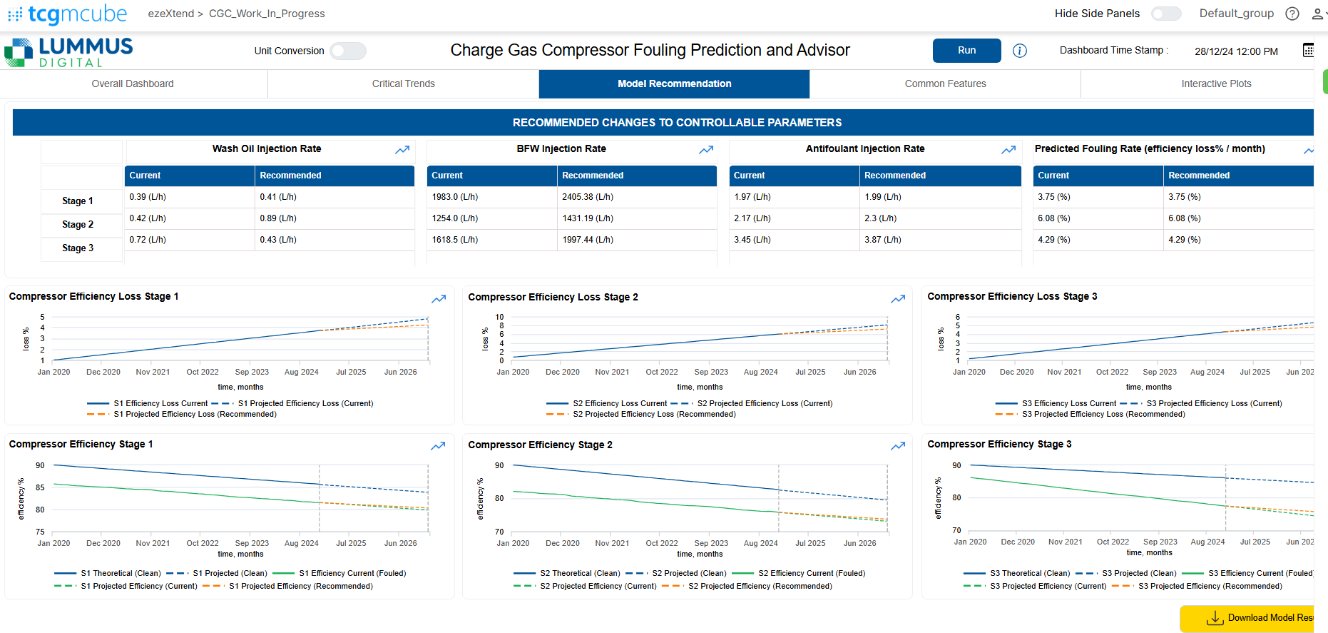

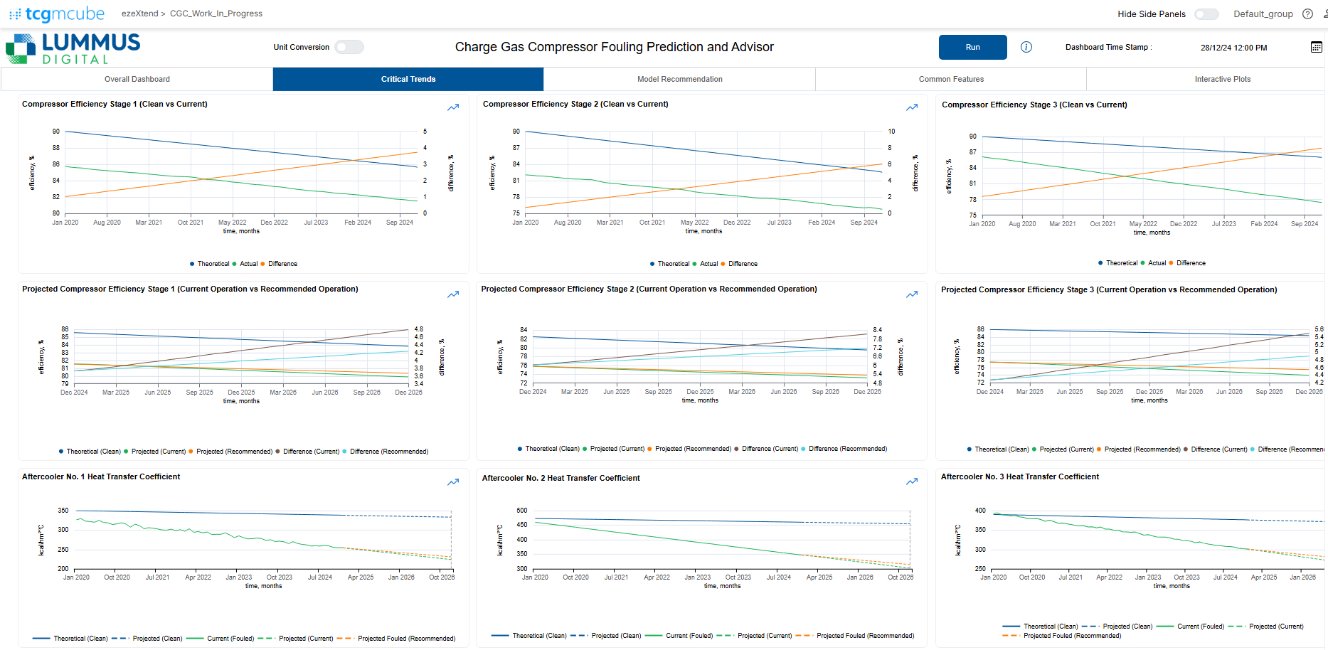

Operational reliability can be improved using digital solutions for:

Anomaly

Detection

Using supervised and unsupervised machine learning, to determine contributing factors for the anomalous behavior of the equipment

Root Cause

Identification

Prediction of Failures Ahead of Occurrence

Using deep learning Long Short-Term Memory (LSTM) of the networks, the prediction of anomalies and remaining time before equipment failure