Lummus Digital enables intelligent plant operations by combining deep process expertise with AI and advanced data analytics. With Hybrid Process Modelling at the core, we drive performance, reliability, and efficiency across the petrochemical industry.

Leveraging autonomous intelligence built into the AI/ML-powered platform mcube™, operations are enhanced by continuously interpreting real-time data, learning from process behavior, and adapting without manual intervention. This delivers context-aware insights tailored to evolving plant conditions—enabling timely actions that improve asset availability, ensure product quality, and maintain operational stability.

The Look, Listen, and Feel (LLF) automation is particularly valuable for petrochemical operations. It captures operator observations—visual cues, auditory signals, and tactile feedback—and converts them into structured, real-time intelligence that, once integrated into our reliability framework, enhances situational awareness and enables earlier, more accurate detection of potential issues.

Lummus continues to build it capability and expertise in petrochemicals and has a wide-range of solutions that address unique challenges in this industry.

Ethylene Heater

Optimization

Ethylene Fractionator

Optimization

Charge Gas Compressor (CGC)

efficiency monitoring

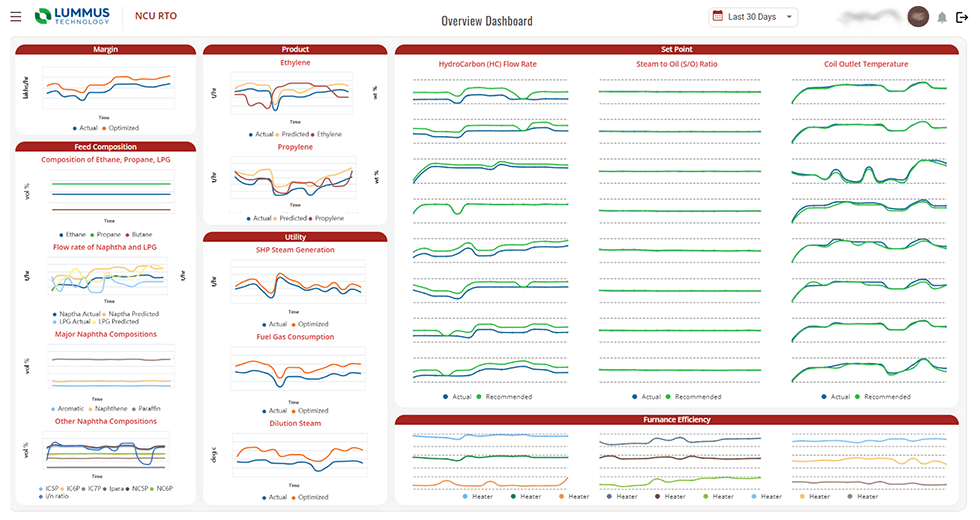

Ethylene Heater Optimization

Designed to enhance the performance of the Naphtha Cracker, this solution utilizes an integrated First-Principles Simulation and AI/ML-powered platform that maximizes margin by predicting Product Quality in real time. Designed for process engineers and plant operators, it helps you run your unit at peak performance, maintain premium product quality, and unlock significant cost savings across your operations.

Pain Point

Struggling to boost throughput and profitability

Benefit

Optimize throughput and profit with precise Heater COT and Steam-to-Oil Ratio adjustments

Pain Point

Uncertainty in determining the ideal Heater COT setpoint

Benefit

Get accurate Heater COT set points tailored to your feed using optimizer insights and PYPS+ analysis

Pain Point

Unclear achievable yield for specific feed compositions

Benefit

Unlock insights with the Scenario Analysis feature, which provides the potential yield based on Naphtha feed composition

Performance Metrics

Performance Deviation Prediction

The PYPS+ Model takes the Plant Feed Composition, Feed rate, and the current DCS operating data as input

Key Parameter Monitoring

Process and Efficiency Trends

Based on the optimizer mode selection and the Scenario Analysis run (PYPS+), the RTO provides setpoints for the operator to achieve the desired results.

Operational Benchmarking

The model re-runs a scenario analysis after the optimizer run is complete to analyze actual results in PYPS+ once the changes are implemented.

Actionable Insights for Improvement

Margins are calculated for before RTO, with RTO, and after RTO to assess profit impact, and the results are published in a report.

Ethylene Heater

Optimization

Ethylene Fractionator

Optimization

Charge Gas Compressor (CGC)

efficiency monitoring

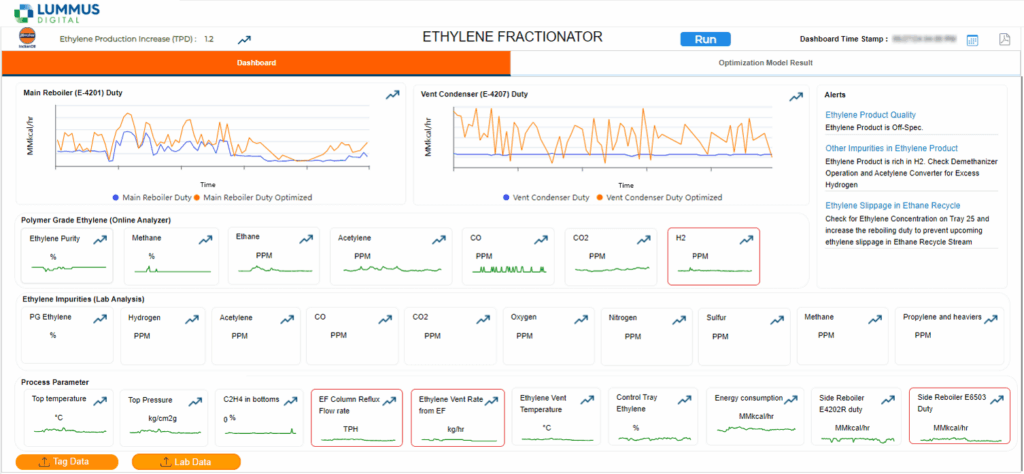

Ethylene Fractionator Optimization

This AI/ML-powered platform is designed to maximize ethylene product yield while minimizing ethylene slippage in the bottom ethane recycle stream. By leveraging real-time DCS data, it optimizes utility consumption and reduces ethylene vent rates. This solution ensures your column runs at peak efficiency—helping you achieve higher ethylene yield, reduce losses, and unlock significant cost savings across your operations.

Pain Point

Ethylene Product Loss & Heater Maintenance Issues

Benefit

Reduced Ethylene Slippage: Optimized reboiling and condensing operations push ethylene quality to spec limits, minimizing product loss

Pain Point

Increased Operational Cost due to higher Vent and Recycle rates

Benefit

Lower Vent & Recycle Rates: Reduced ethylene venting and ethane recycle with minimal slippage

Pain Point

Reduced Ethylene Recovery (Product-to-Feed Ratio)

Benefit

Maximized Ethylene Recovery: Optimized column operations leverage design specification margins to enhance ethylene product yield

Pain Point

High Refrigerant Consumption

Benefit

Optimized Refrigerant Use: Decreased refrigerant consumption and improved recovery through increased reboiling

Performance Metrics

Performance Deviation Prediction

Takes the DCS and LIMS data with respect to the Ethylene Fractionator for further analysis and processing.

Key Parameter Monitoring

Process and Efficiency Trends

The alert indicates if the unit is operating normally (displays “Ethylene Product is on-spec”) or not, and provides recommended operator actions and upcoming event forecasts.

Operational Benchmarking

The model runs and publishes recommended values for operator-controlled setpoints to achieve lower vent rates, minimize ethylene slip, and maximize on-spec ethylene product rates.

Actionable Insights for Improvement

Displays a comparison plot of Current Operation vs. Optimized Operation on the dashboard to highlight potential areas for improvement.

Ethylene Heater

Optimization

Ethylene Fractionator

Optimization

Charge Gas Compressor (CGC)

efficiency monitoring

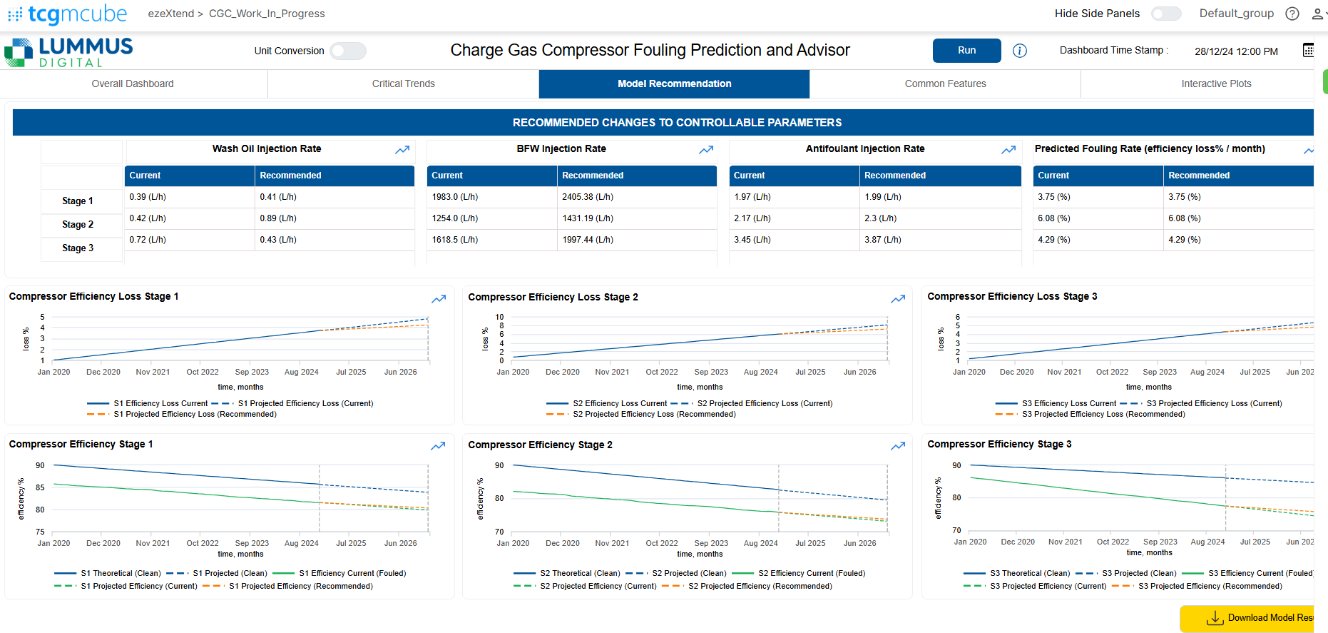

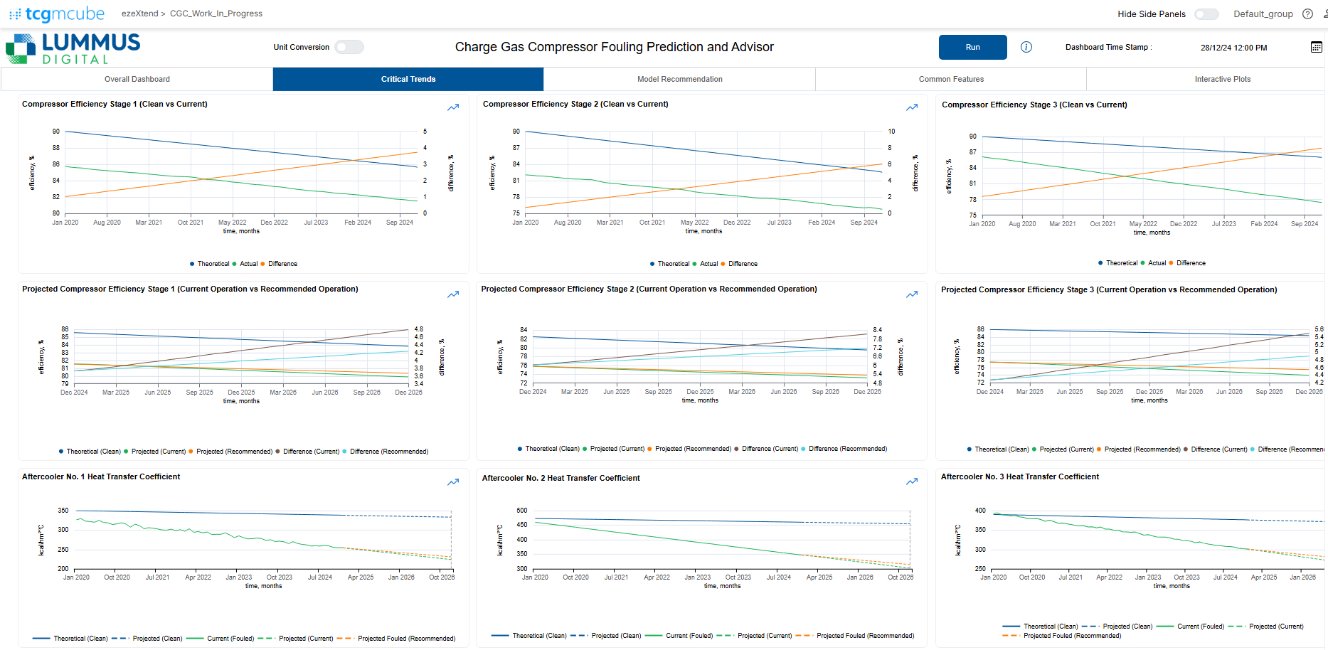

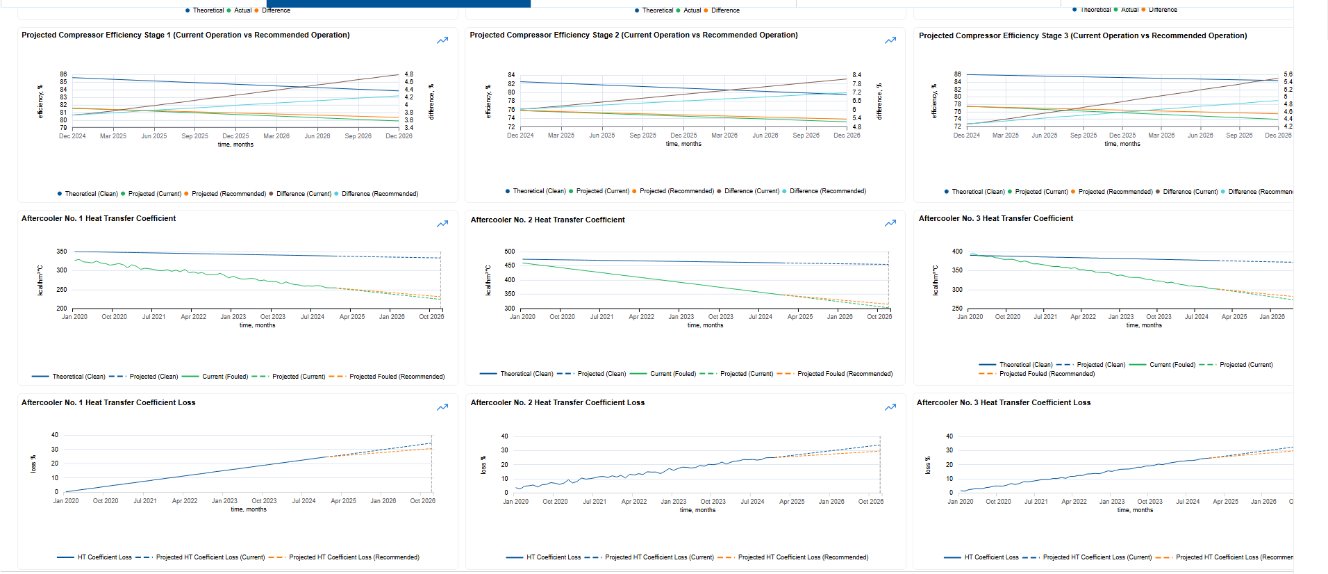

Charge Gas Compressor (CGC) efficiency monitoring

Optimize the operational performance of Charge Gas Compressors (CGC) by predicting and mitigating fouling issues in real-time. Our advanced hybrid model empowers process engineers to maintain optimal efficiency, reduce downtime, and drive cost savings across your operations.

Pain Point

Inability to Predict Fouling Issues in Real-time

Benefit

Real-time monitoring and predictive analytics identify potential fouling issues before they cause operational disruptions.

Pain Point

Difficulty in Managing Multiple Compressor Stages Simultaneously

Benefit

Monitor and manage up to six compressor stages, along with aftercoolers, through a comprehensive and flexible dashboard designed to meet your specific needs.

Pain Point

High Energy Consumption and Operational Inefficiency

Benefit

Optimize energy usage and enhance efficiency with actionable recommendations based on AI-driven insights and hybrid model approaches.

Pain Point

Unplanned Downtime and Increased Operating Costs

Benefit

Minimize unplanned downtime with predictive maintenance capabilities, reducing both costs and operational risks.

Performance Metrics

Performance Deviation Prediction

Predict the fouling rate at each compression stage along with the corresponding fouling rates for related intercoolers and heat exchangers, based on real-time operational data and conditions.

Key Parameter Monitoring

Stage-wise monitoring of compressor parameters, including pressure rise, temperature rise, after-cooler differential pressure (ΔP), and after-cooler differential temperature (ΔT)

Process and Efficiency Trends

Operational Benchmarking

A comparison plot between “Current Operation” and “Recommended Operation” is displayed, allowing for a clear visual assessment of the two operational scenarios.

Actionable Insights for Improvement

Actionable recommendation (comparing with current values) on controllable parameters (each stage- wise) like Wash Water Injection, BFW Injection, Antifoulant Injection, and Fouling Rate.

Petrochemical operators can also benefit from digital solutions that address

fundamental operating issues such as:

Operational reliability

based on:

Anomaly

Detection

Using supervised and unsupervised machine learning, to determine contributing factors for the anomalous behavior of the equipment

Root Cause

Identification

Prediction of Failures Ahead of Occurrence

Using deep learning Long Short-Term Memory (LSTM) of the networks, the prediction of anomalies and remaining time before equipment failure

Best Optimal Solution Recommendation

Polymer production planning

Product Mix Optimization

Optimal Manufacturing Sequencing

Using the production plan, it further recommends optimal manufacturing sequence on the production line to reduce costs and improve time to market